FITTER NIMI BASED ONLINE TEST 1st YEAR

FITTER

NSQF LEVEL – 4

1st Year

QUESTION BANK

SECTOR : Production & Manufacturing

Module – 1 : Safety

Level 1

1 Which one is the personnel safety?

A Keep the machine clean

B Concentrate on your work

C Keep the gang way and floor clean

D Keep the tools at their proper place

2 Name the mandatory symbol ?

A Stop

B Give way

C Guarded

D Unguarded

3 Flammable of liquefiables solids are classified as.

A Class ‘A’ fire

B Class ‘B’ fire

C Class ‘C’ fire

D Class ‘D’ fire

4 Which is the immediate life saving procedure?

A First Aid

B Call a doctor

C Intensive care

D Medical treatment

5 Name the warning sign.

A School

B Guarded

C Unguarded

D Pedestrian crossing

6 What is the class of fire caused by fire wood, paper, cloth?

A Class ‘A’ fire

B Class ‘B’ fire

C Class ‘C’ fire

D Class ‘D’ fire

7 Which fire extinguisher filled with carbon tetra chloride and bromochlorodifluoro methane (BCF)?

A Carbon dioxide

B Halon extinguisher

C Foam extinguisher

D Dry powder extinguisher

8 Which comes under mechanical occupational hazards?

A Noise

B Toxic

C Unskilled

D Unguarded machinery

9 How to stop bleeding of injured person?

A Tie bandage

B Apply oinment

C Apply tincture over the wound

D Apply pressure over the wound

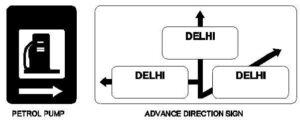

10 What is the name of sign?

A School

B Guarded

C Unguarded

D Pedestrian crossing

11 What are the three factors causes fire?

A Fuel, Heat, Oxygen

B Oxygen, Fuel, Nitrogen

C Heat, Nitrogen, Oxygen

D Fuel, Carbon-dioxide, Heat

12 What is the period referred as ‘golden hours’?

A First 30 minutes after incident

B First 30 minutes after first aid

C First 45 minutes of admission

D First 60 minutes after treatment

13 What is the first step of avoiding accident in work place?

A By wearing safety equipment

B Doing things in one’s own way

C By observing safety precautions

D Doing things with a highly skilled working practice

14 What does the symbol denotes?

A Stop

B Give way

C Pedestrian crossing

D Over taking prohibited

15 What is the colour code of bins for waste paper segregation?

A Red

B Blue

C Black

D Green

16 What is the kind of road sign?

A Police signal

B Cautionary sign

C Mandatory sign

D Information sign

17 Which fire extinguisher is used for flammable and running liquid fire?

A Foam extinguisher

B Halon extinguisher

C Dry powder extinguisher

D Carbon dioxide (CO2) extinguisher

18 What “A” denotes in ABC of first aid ?

A Air way

B Attention

C Arresting

D Atmosphere

19 What is the process of breaking down the materials into organic compounds and can be used as manure?

A Land fills

B Recycling

C Composting

D Burning waste material

20 What is the colour code for plastic waste bin?

A Red

B Blue

C Green

D Yellow

Module – 2 : Basic fitting

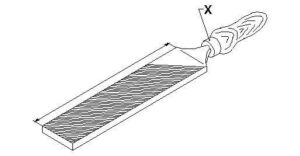

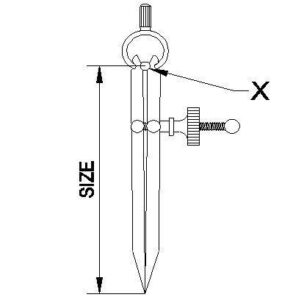

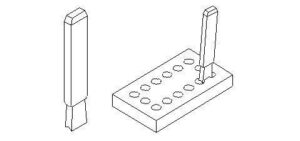

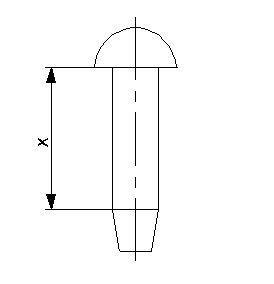

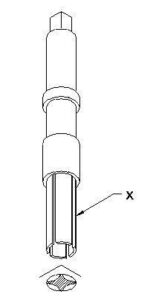

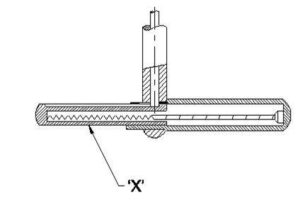

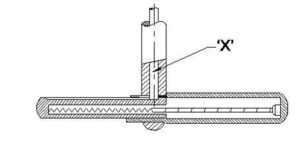

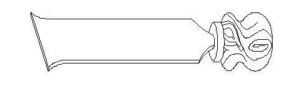

1 Name the part of file marked as “x”.

A Heel

B Tang

C Ferrule

D File length

2 Which marking media is poisonous?

A White wash

B Prussian blue

C Copper sulphate

D Cellulose lacquer

3 What is the name of the vice?

A Pin vice

B Pipe vice

C Hand vice

D Quick releasing vice

4 Which chisel used for squaring materials at the corners, joints?

A Flat chisel

B Cross cut chisel

C Diamond point chisel

D Half round nose chisels

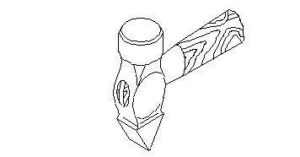

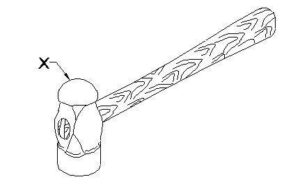

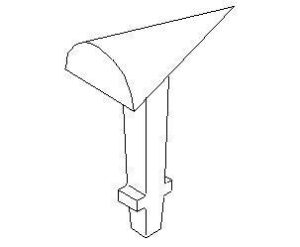

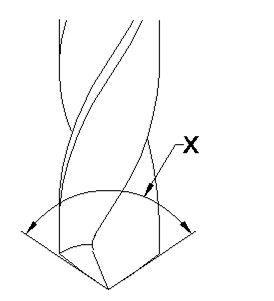

5 Name the part of a hammer marked as ‘x’.

A Face

B Pein

C Cheek

D Eye hole

6 Which angle is represented by the symbol “γ” on the cutting chisel?

A Rake angle

B Wedge angle

C Cutting angle

D Clearance angle

7 Name the property of metal which can be drawn into wire without rupture.

A Ductility

B Tenacity

C Elasticity

D Malleability

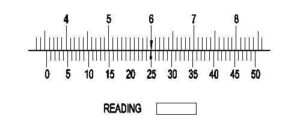

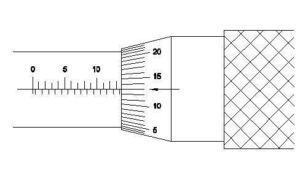

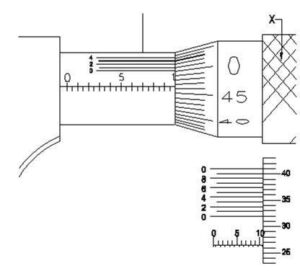

8 Read the measurement in the dial caliper.

A 24.2 mm

B 24.8 mm

C 25.2 mm

D 26.2 mm

9 Which is an integral part of the stock in vernier bevel protractor?

A Disc

B Dial

C Blade

D Main scale

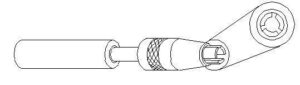

10 Name the part marked as ‘x’ of the file.

A Heel

B Edge

C Ferrule

D Shoulder

11 Which file is used to make the job close to the finishing size?

A Single cut file

B Curved cut file

C Second cut file

D Double cut file

12 Which file has the parallel edges throughout the length?

A Hand file

B Bastard file

C Rasp cut file

D Single cut file

13 What is the material to manufacture bench vice?

A Tool steel

B High carbon steel

C Medium carbon steel

D Cast iron

14 Which marking media provide clear lines on machine finished surfaces?

A White wash

B Prussian blue

C Copper sulphate

D Cellulose lacquer

15 Which caliper is used to mark the centre of round bar?

A Jenny caliper

B Inside caliper

C Outside caliper

D Firm joint caliper

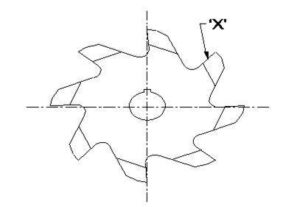

16 Name the part marked as ‘x’.

A Leg

B Peg

C Washer

D Fulcrum

17 Name the angular measuring instrument.

A Bevel gauge

B Bevel protractor

C Universal bevel gauge

D Universal surface gauge

18 Which is used for filling narrow grooves and angles above 10°?

A Square file

B Half round file

C Triangular file

D Knife edge file

19 Which chisel is used for cutting oil grooves?

A Flat chisel

B Web chisel

C Half round nose chisel

D Diamond point chisel

20 Name the file.

A Barrot file

B Riffler file

C Crossing file

D Mill saw file

21 What is the name of vice?

A Pin vice

B Pipe vice

C Hand vice

D Machine vice

22 Which grinding machine is used for heavy duty work?

A Bench grinder

B Portable grinder

C Pedestal grinder

D Surface grinder

23 Which chisel is used for separating materials after chain drilling?

A Web chisel

B Flat chisel

C Cross cut chisel

D Diamond point chisel

24 Which file is used for sharpening the teeth of wood working saws?

A Barrete file

B Tinker’s file

C Millsaw file

D Riffler file

25 Where will be the weight of the hammer stamped?

A Face

B Pein

C Cheek

D Eye hole

26 Name the property of metal to resist the effect of tensile forces without

rupture.

A Ductility

B Tenacity

C Elasticity

D Malleability

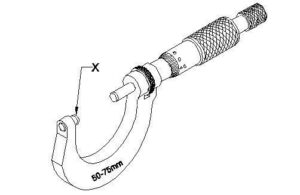

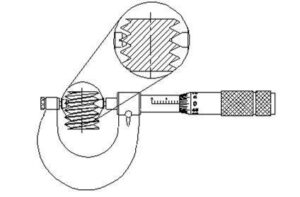

27 Name the part marked as ‘x’.

A Anvil

B Thimble

C Spindle

D Spindle lock

28 What is the accuracy of metric outside micrometer?

A 0.01 mm

B 0.001 mm

C 0.02 mm

D 0.002 mm

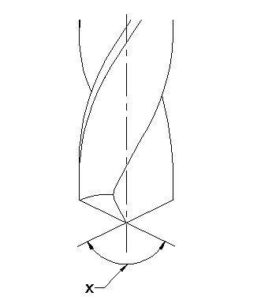

29 Name the part marked as ‘x’.

A Lip

B Land

C Flank

D Point angle

30 Which type of taper is provided in the drill shank?

A Pin taper

B Metric taper

C Morse taper

D Jarno taper

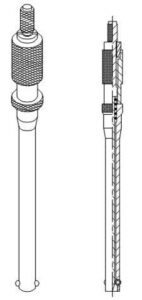

31 Which is used to remove drills and sockets from the machine spindle?

A Drift

B Sleeve

C Punch

D Hammer

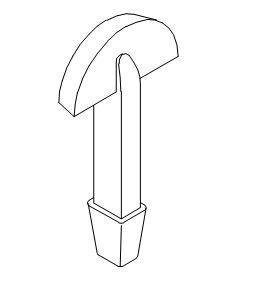

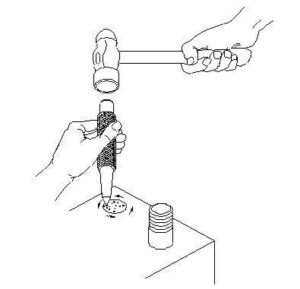

32 Name the tap wrench used in the restricted place.

A Box type tap wrench

B ‘T’ handle tap wrench

C Solid type tap wrench

D Double ended adjustable tap wrench

33 What is the unit of feed in drilling operation?

A m/rev

B mm/rev

C m/min

D mm/min

34 Name the part marked as ‘x’ in vernier caliper.

A Beam

B Fixed bar

C Depth bar

D Thumb lever

35 What is the accuracy of protractor head in combination set?

A 1°

B 5°

C 5’

D 5″

36 What is the accuracy of a try square?

A 0.02 mm per 10 mm length

B 0.004 mm per 10 mm length

C 0.002 mm per 10 mm length

D 0.001 mm per 10 mm length

37 Which punch is used for witness marks?

A Dot punch

B Pin punch

C Bell punch

D Centre punch

38 What is the name of the caliper having one leg with an adjustable divider point and other leg is bent?

A Jenny caliper

B Inside caliper

C Outside caliper

D Spring joint caliper

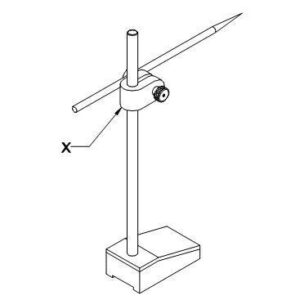

39 What is the name of part marked as ‘x’ in surface gauge?

A Nut

B Snug

C Spindle

D Scriber

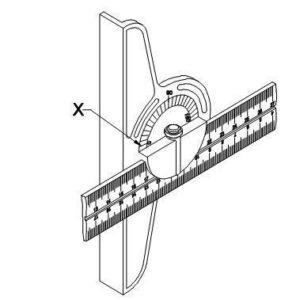

40 What is the name of part marked as ‘x’ in combination set?

A Bevel head

B Centre head

C Square head

D Protractor head

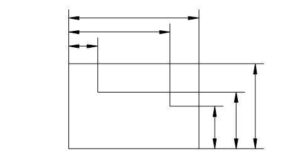

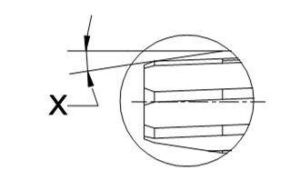

41 Which type of datum is followed?

A Edge datum

B Point datum

C Centre line datum

D Reference line datum

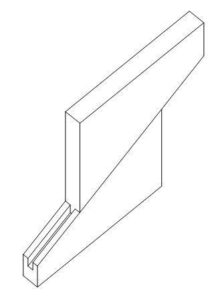

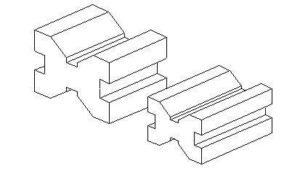

42 What is the name of parallel block?

A Solid parallel block

B Tenon parallel block

C Angular parallel block

D Adjustable parallel block

43 Which chisel is used for removing materials on the corners of the keyways?

A Flat chisel

B Diamond point chisel

C Cross cut chisel

D Half round nose chisel

44 Which file is having rows of teeth cut in one direction?

A Single cut file

B Curved cut file

C Second cut file

D Double cut file

45 Which file is used for filing wood and leather?

A Hand file

B Bastard file

C Rasp cut file

D Single cut file

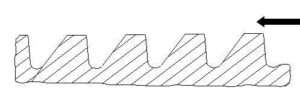

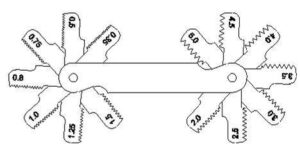

46 Which pitch of blade is used for cutting bronze, brass and cast iron?

A 0.80 mm

B 1.00 mm

C 1.40 mm

D 1.80 mm

47 Which type of hammer is used for riveting purpose?

A Sledge hammer

B Ball pein hammer

C Cross pein hammer

D Straight pein hammer

48 What is the unit of cutting speed in drilling operation?

A metre/ rev

B mm/ rev

C m/ min

D mm/ min

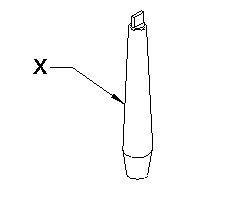

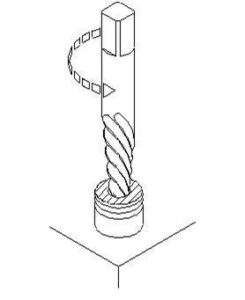

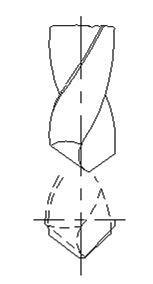

49 What is the name of part marked as ‘x’ in drill?

A Lip

B Land

C Flank

D Web

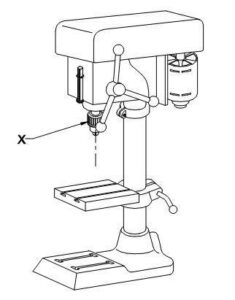

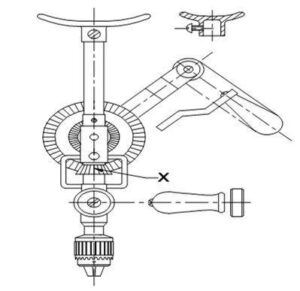

50 What is the name of part marked as ‘x’ in drilling machine?

A Drill chuck

B Feed handle

C Driving motor

D Depth gauge and stop

51 What is the minor diameter of thread?

A Minor dia = Major dia – (2 x pitch)

B Minor dia = Major dia + (2 x pitch)

C Minor dia = Major dia + (2 x depth)

D Minor dia = Major dia – (2 x depth)

52 What is the name of the part marked as ‘X’?

A Spindle

B Sleeve

C Thimble

D Spindle lock

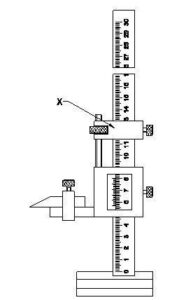

53 What is the name of the part marked as ‘X’?

A Beam

B Main scale

C Fine adjusting nut

D Fine adjusting slide

54 What is the name of the vice?

A Hand vice

B Bench vice

C Tool maker’s vice

D Quick releasing vice

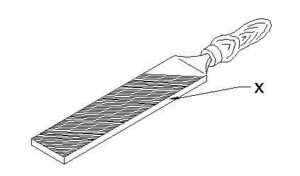

55 What is the name of the part marked as ‘X’?

A Tip

B Heel

C Tang

D Safe edge

56 Which marking media is applied to rough forgings and castings?

A White wash

B Prussian blue

C Copper sulphate

D Cellulose lacquer

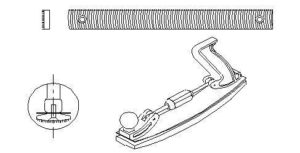

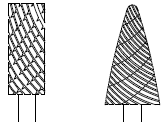

57 Name the file shown.

A Riffler file

B Tinkers file

C Barrette file

D Crossing file

58 What is the pitch of hacksaw blade used to cut conduit and other thin tubes?

A 0.8mm

B 1.0mm

C 1.4mm

D 1.8mm

59 Which metal cutting saw is used for cutting different profiles?

A Power saw

B Circular saw

C Contour band saw

D Horizontal band saw

60 What is the name of chisel?

A Flat chisel

B Web chisel

C Cross cut chisel

D Diamond point chisel

61 What is the name of hammer?

A Mallet hammer

B Ball pein hammer

C Cross pein hammer

D Straight pein hammer

62 What is the name of angle between the axis of chisel and job surface while chipping?

A Rake angle

B Point angle

C Clearance angle

D Angle of inclination

63 What is the property of metal that permits no permanent distortion before breaking?

A Tenacity

B Hardness

C Brittleness

D Toughness

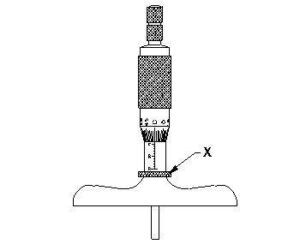

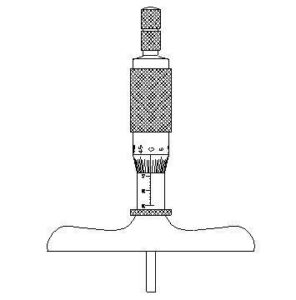

64 Name the part marked as ‘x’ in depth micrometer.

A Cap

B lock

C Stock

D Thimble

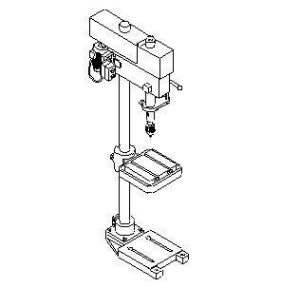

65 What is the name of drilling machine?

A Pillar drilling machine

B Gang drilling machine

C Bench drilling machine

D Radial drilling machine

66 What is the accuracy of vernier bevel protractor?

A 1°

B 5°

C 5′

D 5″

67 What is the reading of vernier caliper?

A 30.20mm

B 30.40mm

C 35.20mm

D 35.50mm

68 Which part of universal surface gauge is used to set scriber at required position exactly?

A Snug

B Guide pin

C Rocker arm

D Fine adjustment screw

69 Convert one metre into millimetre.

A 10 mm

B 100 mm

C 1000 mm

D 10000 mm

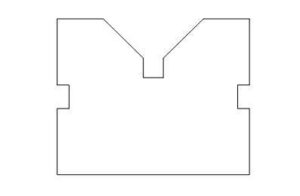

70 What is the name of ‘V’ block?

A ‘V’ grooved ‘V’ block

B Single level single groove ‘V’ block

C Double level single groove ‘V’ block

D Single level double groove ‘V’ block

71 What is the name of the part marked as ‘x’ in combination set?

A Rule

B Scriber

C Clamp nut

D Spirit level

72 Which caliper is used to find the centre of round bars?

A Inside caliper

B Jenny caliper

C Vernier caliper

D Outside caliper

73 What is the name of angle marked ‘α’ in chisel?

A Rake angle

B Wedge angle

C Cutting angle

D Clearance angle

74 Which chisel is used for cutting curved grooves?

A Flat chisel

B Web chisel

C Cross cut chisel

D Half round nose chisel

75 What is the weight of hammer used for marking purpose?

A 200 grams

B 250 grams

C 300 grams

D 450 grams

76 Which chisel is used to remove excess metal from welded joint and castings?

A Flat chisel

B Web chisel

C Cross cut chisel

D Half round chisel

77 What is the name of file?

A Rotary file

B Tinkers file

C Barrette file

D Crossing file

78 What is the name of portion left between flutes in a drill?

A Lip

B Web

C Point

D Shank

79 What is the reading of vernier bevel protractor?

A 27° 30’

B 67° 30’

C 157° 30’

D 159° 30’

80 Which part of outside micrometer ensure a uniform pressure between the

measuring surface?

A Anvil

B Thimble

C Spindle lock

D Ratchet stop

81 Which part of the vernier height gauge is an intergral part of the main

slide?

A Jaw

B Base

C Beam

D Jaw clamp

82 Which part of the bevel protractor contact with the inclined surface while measuring?

A Dial

B Disc

C Blade

D Stock

83 Which part in drilling machine is to achieve different speed?

A Flat pulley

B Jockey pulley

C Stepped pulley

D Fast and loose pulley

84 What is the part marked as ‘x’ in pedestal grinder?

A Tool rest

B Eye shield

C Wheel guard

D Grinding wheel

85 What is the name of file?

A Hand file

B Rasp cut file

C Single cut file

D Curved cut file

86 What happens if the vice handle is over tightened?

A Spindle damage

B Hard jaw damage

C Fixed jaw damage

D Movable jaw damage

87 Which metal cutting saw is used to cut large cross section area?

A Power saw

B Contour saw

C Circular saw

D Horizontal band saw

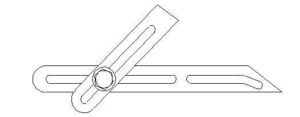

88 What is the name of gauge?

A Bevel gauge

B Angle gauge

C Surface gauge

D Universal bevel gauge

89 Which file is used for manufacturing of dies and moulds?

A Rotary file

B Tinkers file

C Barrette file

D Rasp cut file

90 Which vice is used for holding small work that requires filing or drilling?

A Pin vice

B Pipe vice

C Hand vice

D Tool maker’s vice

91 Which hacksaw blade is used for cutting along curved lines?

A HSS blade

B All hard blade

C Flexible blade

D Diamond blade

92 Which chisel is used for cutting keyways?

A Flat chisel

B Cross cut chisel

C Punching chisel

D Diamond point chisel

93 Name the part marked “X” in hammer?

A Pein

B Face

C Cheek

D Eye hole

94 Name the property of metal that withstand shock or impact?

A Tenacity

B Hardness

C Brittleness

D Toughness

95 What is the name of micrometer?

A Depth micrometer

B Inside micrometer

C Vernier micrometer

D Outside micrometer

96 What is the name of tap wrench?

A Box type tap wrench

B Solid type tap wrench

C ‘T’ Handle tap wrench

D Adjustable tap wrench

97 What is the reading of vernier caliper with inch graduations?

A 1.068″

B 1.459″

C 1.418″

D 1.409″

98 Which part of combination set is used to mark and check angle of 90° and 45°?

A Rule

B Centre head

C Square head

D Protractor head

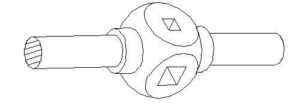

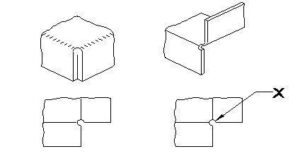

99 Identify the type of “V” blocks?

A Single level single groove

B Single level double groove

C Double level single groove

D Double level double groove

100 How much carbon content of steel is forgeable?

A Up to 1.2 %

B Up to 1.7 %

C Up to 1.9 %

D Up to 2.1 %

Level 2

1 What is the use of a try square?

A To check right angle

B To check acute angle

C To check obtuse angle

D To check straight angle

2 Which part of universal surface gauge holds the scriber?

A Snug

B Guide pin

C Rocker arm

D Fine adjustment screw

3 Why breakage of teeth occur easily while sawing of thin walled work pieces

and the start of cut?

A Hand force is too big

B Cutting section is too short

C Coarse blade to be used

D Hand force acts only upon few teeth

4 What is the spindle movement of one division of thimble with spindle thread

of 0.5mm pitch?

A 0.01 mm

B 0.10 mm

C 1.00 mm

D 10.0 mm

5 What is the reading of a vernier caliper?

A 35.1 mm

B 35.2 mm

C 35.3 mm

D 35.4 mm

6 What is the reading of vernier bevel protractor?

A 18° 50′

B 41° 50′

C 50° 50′

D 58° 50′

7 What is the use of feeler gauge?

A Check the width

B Check the height

C Check the length

D Check the gap between the mating parts

8 What operation is carried out in a gang drilling machine?

A Idle operation

B Repeated operation of drilling

C Continuous milling operation

D Successive operation of drilling

9 What is the purpose of slots provided in the slotted angle plate?

A Job clamping

B Easy handling

C Reduce weight

D Better appearance

10 In the ISO metric thread, calculate the tap drill size for M 10 x 1.5 thread.

A 8.2 mm

B 8.7 mm

C 8.75 mm

D 8.65 mm

11 Which material is used to manufacture grade ‘A’ ‘V’ blocks?

A Tool steel

B Carbon steel

C High quality steel

D Closely grained cast iron

12 Why the cutting faces of files are slightly bellied on length wise?

A Get proper grip over workpiece

B Filing flat surfaces is made easier

C Permit clearance between file face and the workpiece

D Ensure more pressure on workpiece while filing

13 What is the reading of the outside micrometer 50 to 75mm?

A 63.63 mm

B 63.00 mm

C 63.36 mm

D 63.13 mm

14 What is the name of operation?

A Marking line at 90°

B Checking flatness

C Checking squareness

D Setting work piece at right angle

15 Which is used to finish the resharpened divider point?

A File

B Grinder

C Scraper

D Oil stone

16 What is the use of bevel protractor?

A Check the length

B Set the work piece

C Measure the angle

D Measure the depth

17 Which vice is used for holding hollow cylindrical jobs?

A Pin vice

B Pipe vice

C Hand vice

D Bench vice

18 Why slight convexity is given on the face of hammer?

A To make effective striking

B To avoid digging of the edge

C To allow even load on striking

D To prevent damage to work surface

19 Why the hand taps are chamfered at the lead?

A Aligning

B Finishing

C Strengthening

D Gripping

20 What is the reading of an outside micrometer (British)?

A 0.309″

B 0.329″

C 0.359″

D 0.360″

21 Why surface plates are made of stress relieved good quality cast iron?

A To prevent corrosion

B To prevent breaking

C To prevent distortion

D To prevent thermal expansion

22 What is the main advantage of adjustable parallel block?

A To set different angle

B To set different depth

C To set different length

D To set different height

23 Why chalk is applied on the face of the file?

A To reduce excessive pressure

B To increase chip removed rate

C To reduce penetration and pinning

D To increase penetration and pinning

24 What is the use of fine pitch hacksaw blades?

A To cut soft metal

B To cut high speed steel

C To cut high carbon steel

D To cut conduit and other thin tubes

25 Calculate the tap drill size for M10 x 1.25.

A 8.8 mm

B 8.7 mm

C 8.75 mm

D 8.65 mm

26 What is the principle of micrometer?

A Sliding

B Screw and nut

C Rack and pinion

D Worm and worm wheel

27 How the wide range of depth can be measured by depth micrometer?

A Lengthy sleeve

B Lengthy spindle

C Adjustable base

D Equipped with a set of extension rods

28 What is the reading in inch micrometer?

A 0.789″

B 0.787″

C 0.783″

D 0.715″

29 Which caliper provide fine adjustment of dimensions?

A Inside caliper

B Odd leg caliper

C Outside caliper

D Spring joint caliper

30 Why marking tables are made up of cast iron?

A Self lubricating

B Make more rigidity

C Maintain the accuracy

D Prevent thermal expansion

31 What is the method of removing metal chips clogged between the teeth of files?

A Brush

B Wire brush

C Copper strip

D Chalk powder

32 What is the purpose of “Crowning” on the cutting edge of chisel?

A Prevent slipping of chisel

B Prevent digging of corners

C Allow chisel to move freely on straight line

D Allow cutting edge to penetrate into the work

33 Which part is the measuring face fitted to the frame of outside micrometer?

A Anvil

B Barrel

C Spindle

D Ratchet stop

34 How the drill chucks are held on the machine spindle?

A By arbor

B By sockets

C By sleeves

D By special clamp

35 Which drilling machine, the spindle head is moved towards or away from the column?

A Pillar drilling machine

B Gang drilling machine

C Radial drilling machine

D Sensitive bench drilling machine

36 Which type of screw threads are rounded at the crest and root?

A B.A thread

B B.S.F thread

C B.S.W thread

D ACME thread

37 What is the formula to calculate tap drill size?

A Tap drill size = Major dia – (2 x depth)

B Tap drill size = Major dia + (2 x depth)

C Tap drill size = Major dia – (2 + depth)

D Tap drill size = Major dia + (2 + depth)

38 Why ribs are provided in the angle plate?

A Provide flatness

B Prevent distortion

C Provide squareness

D Support the machined surface

1 A new hacksaw blade after a few stroke, becomes loose because of?

A Stretching of blade

B Wrong pitch of the blade

C Improper selection of saw sets

D nut thread being worn out

2 Name the defect that causes the metal chips to clog between the teeth of file?

A File bite

B Pinning of file

C Warping of file

D Glazing of file

3 What will be the effect if the clearance angle of chisel is less than recommended angle while chipping?

A Cutting edge cannot penetrate, chisel will slip

B Cutting edge digs in, cut will be deeper

C Cutting edge will break

D Cutting edge of chisel move freely on straight line

4 What happen if the clearance angle of chisel is too high?

A Slipping of chisel

B Digging on the surface

C Cutting edge will break

D Heavy metal removal from the surface

5 What is the reason for scratches produced on field surface?

A Pinning

B Glazing

C File bite

D Warping

6 What is the effect of improper method of diagonal filing?

A Uneven surface finish

B Scratches on the surface

C Convexity on the surface

D Improper finish on surface

7 How to prevent the tool rubbing against the work surface in metal cutting

process?

A Decrease lip angle

B Increased rake angle

C Increase clearance angle

D Decrease tool wedge angle

8 Which activity causes excessive wear and chattering of drill bit while

drilling?

A Too fast feed rate

B Too slow feed rate

C More cutting speed

D Too slow spindle speed

Module – 3 : Sheet Metal

1 Which cutting fluid is used for drilling in cast iron?

A Dry air jet

B Soluble oil

C Mineral oil

D Vegetable oil

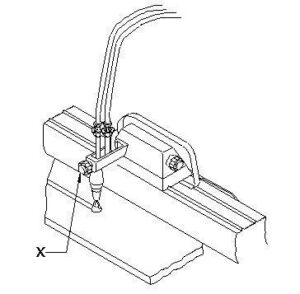

2 Name the part marked as ‘x’ in Radial drilling machine?

A Base

B Spindle

C Radial arm

D Spindle head

3 Which one is used to bring the plates closely together after inserting the

rivet in the hole?

A Drift

B Dolly

C Rivet set

D Caulking tool

4 Name the part of lever shear marked as ‘x’?

A Base plate

B Lever arm

C Lower blade

D Upper blade

5 Name the sheet metal operation?

A Grooving

B Notching

C Bending

D Folding

6 Name the zinc coated iron?

A Black iron

B Tinned iron

C Stainless steel

D Galvanised iron

7 Which sheet metal is highly resistant to corrosion and abrasion?

A Copper

B Black iron

C Aluminium

D Galvanised iron

8 What is the formula to calculate the size across flat to flat of regular

hexagon?

A 2a

B 2a

C √3a

D 3a

9 What is the material of solder?

A Welding rod

B Synthetic element

C Pure metal or alloy

D Non metallic element

10 Which flux used for soldering steel?

A Ammonium chloride

B Zinc chloride

C Resin

D Paste

11 What is the material used to manufacture rivets?

A Rubber

B Synthetic

C Hardened steel

D Mild steel

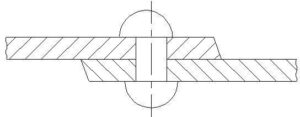

12 Name the part marked as ‘x’ in a rivet?

A Tail

B Body

C Head

D Diameter

13 Which rivet is used in heavy structural work?

A Pan head rivet

B Snap head rivet

C Counter sunk rivet

D Conical head rivet

14 What is the name of tool is used to support the snap head rivet?

A Dolly

B Drift

C Rivet set

D Rivet snap

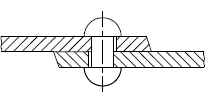

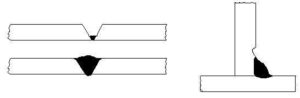

15 Name the riveting defect shown?

A Improper joining of plates

B Burrs between plates

C Rivet head not centred with the shank

D Body of the rivet not perpendicular to the plate

16 Which tool used in sheet metal work to scribe a circle or arc with a large diameter?

A Spring compass

B Trammel

C Wing compass

D Ordinary compass

17 What is the name of part marked ‘X’?

A Body

B Clamp

C Upper blade

D Lower blade

18 Which rivets are used in light assembly work?

A Pan head rivet

B Snap head rivet

C Counter sunk rivet

D Conical head rivet

19 What is the tool used to form the other end of rivet head?

A Dolly

B Drift

C Rivet set

D Rivet snap

20 What is the name of the notch in sheet metal work?

A ‘V’ notch

B Slant notch

C Square notch

D Straight notch

21 What type of mallet used for hollowing panel beating?

A Brass mallets

B Rubber mallets

C Wooden mallets

D Bossing mallets

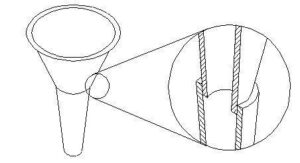

22 Which stake is used to form an arc of a circle bevelled along one side?

A Funnel stake

B Hatchet stake

C Half moon stake

D Beak or bick iron

23 What is the name of supporting tool in sheet metal work?

A Hatchet stake

B Funnel stake

C Half moon stake

D Round bottom stake

24 What is the name of the joint in sheet metal?

A Grooved joint

B Pane down joint

C Knocked up joint

D Double grooved joint

25 What is the maximum cutting capacity of snip?

A 1.2 mm thickness

B 2.0 mm thickness

C 2.5 mm thickness

D 3.0 mm thickness

26 What is the name of supporting tool in sheet metal work?

A Funnel stake

B Hatchet stake

C Half moon stake

D Round bottom stake

27 Which riveting tool is used to form the final shape of rivet?

A Drift

B Dolly

C Rivet set

D Rivet snap

28 Name the tool used to make fluid tight joint in riveting?

A Drift

B Rivet snap

C Fullering tool

D Caulking tool

29 What is the name of tool used to cut thicker sheets?

A Bend snips

B Lever shears

C Straight snips

D Circle cutting machine

30 Which stake is used for making sharp bends?

A Funnel stake

B Hatchet stake

C Half moon stake

D Beak or bick iron

31 What is the name of stake?

A Horse

B Bick iron

C Funnel stake

D Creasing iron

32 Which flux is used for soldering tin sheets?

A Resin

B Paste

C Zinc chloride

D Ammonium chloride

33 What is the seam used in sheet metal joint for roofing and panelling?

A Lap seam

B Double seam

C Grooved seam

D Double grooved seam

34 What is rivet interference?

A Thickness of sheet

B Diameter of the rivet

C Length to form the head

D Total rivet length required for riveting

35 What is the part marked as ‘x’ in the hand shearing machine?

A Clamp

B Lever arm

C Lower blade

D Upper blade

36 What is the tool marked as ‘x’ in riveting?

A Dolly

B Rivet set

C Fullering tool

D Caulking tool

37 Which tool is used to make fluid-tight joint by pressing the riveted edge plate?

A Dolly

B Drift

C Caulking tool

D Fullering tool

38 Which metal is very soft and heavy in sheet metal work?

A Lead

B Black iron

C Aluminium

D Copper sheet

39 Name the tool marked as ‘X’ in riveting?

A Drift

B Rivet snap

C Caulking tool

D Fullering tool

40 Which hammer is suitable for riveting?

A Plastic hammer

B Ball pein hammer

C Cross pein hammer

D Straight pein hammer

41 Which notch is cut at an angle of 45° to the corner of the sheet metal?

A Wire notch

B Slant notch

C Square notch

D Straight notch

42 Name the joint made by fastening two edges of sheet metal together?

A Hem

B Seam

C Notch

D Groove

43 What is the flux used for soldering in the form of powder and evaporates while heating?

A Resin

B Zinc chloride

C Hydrochloric acid

D Ammonium chloride

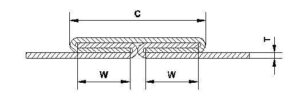

44 Name the type of seam?

A Lap seam

B Double seam

C Grooved seam

D Double grooved seam

45 Which rivet is used to avoid the projection of rivet head?

A Pan head rivet

B Snap head rivet

C Conical head rivet

D Counter sunk head rivet

1 Select the spindle speed (rpm) for H.S.S drill dia 24 mm and cutting speed

(V) = 30 m/min to drill mild steel?

A 275 rpm

B 300 rpm

C 400 rpm

D 450 rpm

2 What is the use of bent snips?

A Groove cut

B Zigzag cut

C Straight cut

D Circular cut

3 Calculate the weight of steel plate having length of 2000 mm, width of 500 mm, thickness of 4 mm and density of 7.85 g/cm3?

A 21.4 Kg

B 31.4 Kg

C 41.4 Kg

D 50.4 Kg

4 What is the use of stakes in sheet metal work?

A Rest of work

B Supporting piece

C Sharpening

D Folding shapes

5 What is the purpose of groover?

A Releasing of seam

B Compress the seam

C Closing and locking of seam

D Stress relieving during seam operation

6 Which is the operation of covering area of the metal with molten solder?

A Pickling

B Swaging

C Seaming

D Tinning

7 What is the use of groover in sheet metal work?

A Releasing of seam

B Compress the seam

C Closing of seam

D Stress relieving during seam operation

8 What is the purpose of hole marked as ‘x’?

A Arrest the crack

B Facilitate easy bending

C Make good appearance

D Allow clearance between the ends

9 How the distance of first rivet is determined from the side edge?

A 3 x dia of rivet

B 2 x dia of rivet

C 2.5 x dia of rivet

D 3.5 x dia of rivet

10 What is the advantage of stakes in sheet metal work?

A Sharpening

B Supporting

C Rest of workpiece

D Protect the tool from damage

11 Why allowance is required while making various types of hems and seams?

A To make good appearance

B To prevent damage to the edges

C To prevent over lapping at the seam

D Maintain correct size and improve the strength

12 Which sheet metal is easiest to joint and solder?

A Tinned plate

B Lead

C Galvanised iron

D Stainless sheet

13 Which sheet metal withstand contact with water and exposure to weather?

A Black iron

B Copper sheet

C Stainless sheet

D Galvanised iron

14 What is the purpose of drift in riveting operation?

A Position the rivet

B Make metal to metal joint

C Align the holes to be riveted

D Prevent damage to rivet head

Level 3

1 Why burr form on the underside of the sheet metal while shearing?

A No clearance

B Hardened metal

C Increase in force

D Excessive clearance

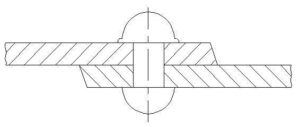

2 What is the fault in riveting?

A Burrs between plates

B Rivet head not centered

C Too much allowance given

D Holes on the plate are not in line

3 What is the name of riveting defect?

A Too little allowance on shank

B Too much allowance on shank

C Rivet head not centered with shank

D Head of rivet not perpendicular to shank

4 What is the reason for faulty rivetting?

A Burrs between plates

B Too little allowance given

C Improper joining of plates

D Too much allowance given

5 What is the fault in riveting?

A Too little allowance

B Burrs between the plates

C Holes on the plate not in line

D Rivet body not perpendicular

6 What is the minimum distance between the rivets to avoid buckling?

A 2 D

B 2.5 D

C 3 D

D 3.5 D

Module – 4 : Welding

1 Which type of filler rod is used in gas welding of stainless steel?

A Pure aluminium

B Copper silver alloy

C Columbium stainless steel

D Copper coated mild steel

2 Name the gas welding defect?

A Porosity

B Lack of fusion

C Oxidised weld

D Incomplete penetration

3 Name the joint in the arc welding?

A Flush corner joint

B Single fillet lap joint

C Half open corner joint

D Full open corner joint

4 Which arc welding machine can be used anywhere in the field work even

away from electric lines?

A Rectifier set

B Motor generator set

C Engine generator set

D AC welding transformer

5 Which arc welding machine provides better heat distribution in the electrode and job?

A Rectifier set

B Motor generator set

C Welding transformer

D Engine generator set

6 What is the colour painted on the acetylene gas cylinders?

A Black

B Green

C Blue

D Maroon

7 What is the angle to be maintained in the blow pipe and filler rod in the left

ward welding technique?

A 60° & 30°

B 50° & 40°

C 30° & 50°

D 60° & 40°

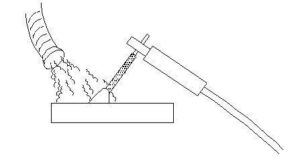

8 Name the safety operation carried out in welding plant shown in the figure?

A Compressor used to force out fuses

B Cooling the surface to clear gases

C Water forced to clean the surface

D Exhaust duct capture fuses and gases

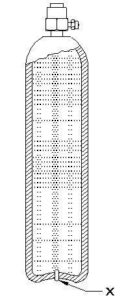

9 Identify the part marked as ‘x’?

A Safety plug

B Steel bottle

C Valve spindle

D Dissolved acetylene

10 What is the name of distortion occurs in the weld direction?

A Angular distortion

B Bending distortion

C Longitudinal distortion

D Transverse distortion

11 What is the name of the metal edge in an angle during welding and cutting operations?

A Kerf

B Drag

C Bevel

D Gouging

12 What is the oxygen cylinder colour?

A Red

B Blue

C Black

D Maroon

13 What is the name of the part marked as ‘X’?

A Handle

B Mixing chamber

C Oxygen control value

D Acetylene control value

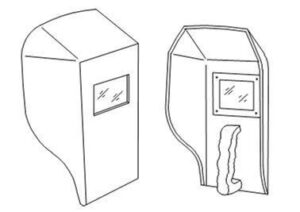

14 What is the name of PPE?

A Portable screen

B Chipping goggles

C Welding hand screen

D Welding helmet screen

15 What is the name of the part marked as ‘X’?

A Preheat control valve

B Oxygen control valve

C Horizontal adjustment

D Vertical adjustment

16 What is the storing capacity of oxygen cylinder?

A 7 m3

B 10 m3

C 14 m3

D 15 m3

17 What is the equipment used to protect the body from flying spark during gas cutting?

A Leather cap

B Leather apron

C Leather shoes

D Cutting goggles

Level 2

1 What is the function of AC welding transformer?

A It converts to low voltage high current ampere

B It converts to high voltage and low current ampere

C It converts to low voltage and low current ampere

D It converts to high voltage and high current ampere

2 What is the disadvantage of AC welding transformer?

A More initial cost

B Not free from arc blow

C More maintenance cost

D Not suitable for welding non ferrous metal

3 Which factor determine the current setting during welding?

A Types of joint

B Position of weld

C Length of electrode

D Diameter of electrode

4 What is the OCV for welding in step-down transformer which reduces the main supply voltage (220 or 440 volts)?

A 40 and 100 volt

B 50 and 100 volt

C 30 and 20 volt

D 20 and 25 volt

5 Which is the welding machine designed to supply both A.C and D.C current for welding ferrous and non-ferrous metals using all types of electrode?

A Rectifier set

B Transformer set

C Motor generator set

D Engine generator set

6 Why the cylinder keys are not removed from the cylinder while welding?

A To prevent gas leak

B To adjust the gas supply

C To open and close frequently

D To close quickly in case of fire

7 Which process blow out the cylinder valve socket before connecting the regulator?

A Cracking

B Back fire

C Flash back

D Pressure testing

8 What is the purpose of cellulosic electrode in arc welding process?

A Very easy to remove the deposited slag

B Used for high strength steel

C It is used for low carbon steel

D It is suitable for all position

9 How to extinguish the flame after use in gas welding?

A Shut off oxygen and dip blow pipe in water

B Shut off oxygen and acetylene valve at a time

C Shut off oxygen valve first next acetylene valve

D Shut off acetylene valve first next oxygen valve

10 Why humming sound effects during arc welding?

A Long arc length

B Speedy welding

C Short arc welding

D Normal arc length

Level 3

1 What will cause if the nozzle touches the molten pool?

A Spark

B Smoke

C Back fire

D Flash back

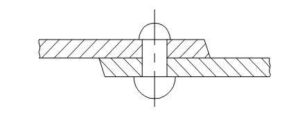

2 Identify the welding defect shown in figure?

A Under cut

B Cracking

C Lack of fusion

D Incomplete penetration

3 Which internal defect welding is invisible to naked eye?

A Spatter

B Porosity

C Undercut

D Stray arc

Module – 1 : Drilling

1 What is the name of the angle marked ‘x’ in the reamer?

A Rake angle

B Flute angle

C Helix angle

D Clearance angle

2 What is the angle of countersinking for riveting?

A 75°

B 80°

C 90°

D 120°

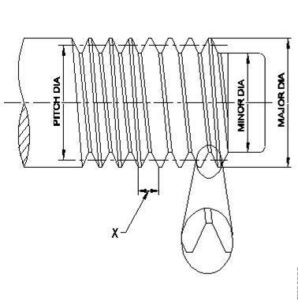

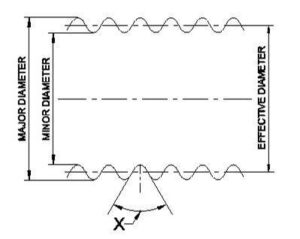

3 What is the name of the element marked ‘x’ of the thread?

A Root

B Lead

C Pitch

D Flank

4 What ‘A’ represents in grinding wheel specification 32A46H8V ?

A Grade

B Grain size

C Type of bond

D Type of abrasive

5 What is the product obtained from blast furnace?

A Pig iron

B Cast iron

C Wrought iron

D Malleable iron

6 Which metal is used to manufacture magnets, ball bearing and cutting tool?

A Cobalt

B Cadmium

C Vanadium

D Molybdenum

7 How much copper contains in pyrites ore?

A 15%

B 32%

C 50%

D 45%

8 Which metal is resistant to many types of acids?

A Tin

B Nickel

C Lead

D Chromium

9 Which method is suitable to remove the broken stud very near to the surface?

A Ezy out method

B Making drill hole

C Prick punch method

D Using square taper punch

10 What is the angle of counter sink head screws?

A 60°

B 90°

C 105°

D 120°

11 What is the name of the angle in the drill bit marked ‘x’?

A Chisel angle

B Rake angle

C Point angle

D Lip clearance angle

12 Which angle is determined by the helix angle in drill bit?

A Point angle

B Rake angle

C Chisel angle

D Clearance angle

13 Which reamer will have a long taper lead?

A Hand reamer

B Socket reamer

C Machine reamer

D Helical fluted reamer

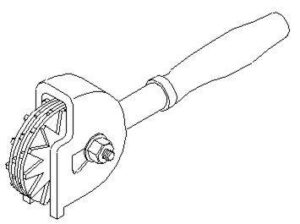

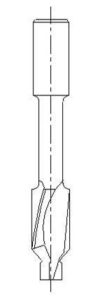

14 What is the name of the tool?

A Stone dresser

B Diamond dresser

C Star wheel dresser

D Abrasive stick dresser

15 Which indicates the strength of bond in grinding wheel?

A Grid

B Grade

C Structure

D Grain size

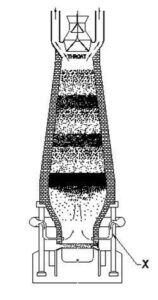

16 What is the name of the part marked ‘x’ in blast furnace?

A Tuyeres

B Molten slag

C Molten iron

D Tapping hole

17 What is the range of carbon content in cast iron?

A 2 to 4%

B 5 to 9%

C 6 to 9%

D 10 to 12%

18 What is the name of the part marked ‘x’ in vernier micrometer?

A Anvil

B Barrel

C Thimble

D Ratchet stop

19 What is the name of part marked as ‘X’?

A Heel

B Cutting edge

C Position rake angle

D Negative rake angle

20 Which reamer is used for reaming internal Metric morse tapered holes?

A Helical fluted reamer

B Hand reamer with pilot

C Taper pin hand reamer

D Socket reamer with parallel shank

21 Name the type of the reamer?

A Hand reamer

B Helical reamer

C Machine reamer

D Taper pin reamer

22 What is the name of part marked as ‘X’?

A Arbor

B Drill chuck

C Drill bit

D Chuck key

23 Which reamer has a long taper lead?

A Socket reamer

B Hand reamer

C Machine reamer

D Helical fluted reamer

24 Which cast iron has the ability to reduce vibration and tool chattering in machine tools?

A Grey cast iron

B White cast iron

C Nodular cast iron

D Malleable cast iron

25 Which furnace is used to produce wrought iron?

A Blast furnace

B Cupola furnace

C Puddling furnace

D Electric arc furnace

26 Which ore is used to extract zinc?

A Bauxite

B Galena

C Calamine

D Cassiterite

27 Which tool is used to check the internal clearance of the bearing?

A Steel rule

B Feeler gauge

C Depth gauge

D Vernier caliper

28 What is the name of part marked as ‘X’?

A Collar

B Square head

C Fingers

D Body

29 What is the angle of ACME thread?

A 66°

B 55°

C 29°

D 45°

30 What is the name of elements of screw marked as ‘X’?

A Root

B Pitch

C Crest

D Thread angle

31 What is the helix angle of general purpose drill?

A 59°

B 118°

C 27.5°

D 8° to 12°

32 What is the name of the tool?

A Pilot drill

B Counter sink

C Drill with pilot

D Countersink with pilot

33 Which part of a reamer is designed for the removal of chips?

A Face

B Flute

C Heel

D Cutting edge

34 What is the name of operation?

A Drilling

B Spot facing

C Countersinking

D Counter boring

35 What is the term, the top surface joining the two sides of a thread?

A Root

B Crest

C Flank

D Pitch

36 What ‘V’ denotes in grinding wheel specification 32A46H8V?

A Bond

B Grade

C Abrasive

D Grain size

37 What type of abrasive wheel is used for grinding die steel?

A Silicon carbide

B Green silicon carbide

C White aluminium oxide

D Brown aluminium oxide

38 Which term indicates the amount of bond present between the individual abrasive grains?

A Grain

B Grade

C Abrasive

D Structure

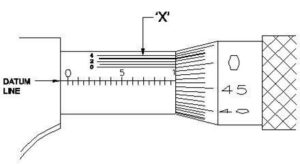

39 What is the name of the part marked as ‘X’ in vernier micrometer?

A Barrel

B Thimble

C Datum line

D Vernier division

40 What is the name of the part marked as ‘X’ of telescopic gauge?

A Spring

B Handle

C Fixed leg

D Telescoping leg

41 What is the name of the tool?

A Reamer

B Spot facing tool

C Countersink tool

D Counter boring tool

42 What is the name of the angle marked as ‘X’ in drill bit ?

A Helix angle

B Lead angle

C Point angle

D Chisel edge angle

43 What is the name of element marked as ‘X’ in reamer?

A Face

B Heel

C Flute

D Cutting edge

44 Which angle determines the rake angle of drills?

A Helix angle

B Core angle

C Point angle

D Chisel edge angle

45 What is the angle of countersink tool used on holes to be threaded?

A 75°

B 80°

C 90°

D 120°

46 What is the name of the die?

A Split die

B Half die

C Solid die

D Adjustable screw plate die

47 Which type of thread, the crest and roots are rounded to form a semi circle?

A Acme thread

B Square thread

C Knuckle thread

D Trapezoidal thread

48 What ‘5’ denotes in grinding wheel specification 41A46H5U8?

A Bond

B Abrasive

C Structure

D Grain size

49 Which type of bonded wheel is used in foundries for dressing castings?

A Silicate bond

B Shellac bond

C Rubber bond

D Resinoid bond

50 What type abrasive wheel is used for grinding cemented carbides?

A Green silicon carbide

B Grey aluminium oxide

C White aluminium oxide

D Brown aluminium oxide

51 What is the value of one vernier division of a vernier micrometer?

A 0.01 mm

B 0.02 mm

C 0.009 mm

D 0.002 mm

52 What is the name of part marked as ‘X’ in telescopic gauge?

A Handle

B Fixed leg

C Plunger lock

D Telescopic leg

53 What is the method of removing broken stud?

A Ezy-out

B Prick punch

C Making drill hole

D Using square taper punch

54 What is the name of the part marked as ‘X’?

A Breast plate

B Bevel pinion

C Frame work

D Locking screw

55 What is the name of part marked as ‘X’ in hand reamer?

A Taper lead

B Bevel lead

C Circular lead

D Taper lead angle

56 What is the counter sink angle of chamfering in the end of drilled hole for threading?

A 75°

B 80°

C 90°

D 120°

57 What is the name of thread?

A Vee thread

B Buttress thread

C Square thread

D Saw – tooth thread

58 What is the name of part marked ‘X’?

A Root

B Pitch

C Crest

D Helix angle

59 What is the included angle of metric ‘V’ threads?

A 45°

B 29°

C 60°

D 47½°

60 What ’46’ represent in standard marking system of grinding wheel (32A46H8V)?

A Grade

B Grain size

C Type of bond

D Type of abrasive

61 What is the tool used in grinding operation?

A Honing tool

B Abrasive stick

C Diamond dressers

D Star wheel dressers

62 What is the colour of aluminium metal?

A Dull white

B White

C Bright white

D Bluish grey colour

63 What ‘H’ denotes in the specifications of grinding wheel 32A46H8V?

A Grain sze

B Type of abrasive

C Grade

D Structure

64 What is produced from blast furnance ?

A Pig iron

B Cast iron

C Wrought iron

D Malleable iron

65 What is the minimum dimension can measure with telescopic gauge?

A 8.0 mm

B 12.7 mm

C 19.0 mm

D 150 mm

66 Which gauge is used to measure below 8 mm dimension?

A Telescopic gauge

B Small hole gauge

C Depth micrometer

D Inside micrometer

Level 2

1 What is the name of the process of finishing the drilled hole?

A Reaming

B Spot facing

C Counter boring

D Counter sinking

2 What is the purpose of clearance angle in twist drill?

A Prevent rough holes

B Prevent over size holes

C Prevent unequal angle of cutting edges

D Prevent friction of drill behind the cutting edges

3 What is the name of the operation to enlarge the hole for given depth?

A Reaming

B Spot facing

C Counter boring

D Counter sinking

4 What is to be done after mounting the new grinding wheel to run concentric?

A Truing

B Glazing

C Loading

D Dressing

5 What is the use of telescopic gauge?

A Measure depth

B Measure external dimension

C Measure angular dimension

D Measure size of holes, slots

6 What is the use of reamer?

A Drill a hole

B Enlarging a hole

C Threading a hole

D Finishing to correct size of the drilled hole

7 What is the purpose of type “N” twist drills?

A Used for hard material

B Used for brittle material

C Used for soft and tough material

D Used for normal low carbon steel

8 What is the function of pilot in the hand reamer with pilot?

A Keep size of hole accurate

B Removes the burr from the hole

C Provide smooth functioning of reamer

D Keep reamer concentric with hole to be reamed

9 Which decides the point angle of drill?

A Drill material

B Job material

C Cutting speed

D Size of the drill

10 What is the drill size for reaming a 10 mm hole, if under size is 0.2mm and

over size is 0.05mm?

A 8.5 mm

B 9.75 mm

C 10.00 mm

D 10.25 mm

11 What is the method of removing the broken stud?

A Ezy- out method

B Prick punch method

C Making drill hole method

D Using square taper punch method

12 What is the operation of beveling the end of a drilled hole?

A Reaming

B Spot facing

C Counter boring

D Counter sinking

13 Why centre screw is provided in the die stock?

A To tighten the die

B To adjust the depth of cut

C To adjust the dia of internal thread

D To adjust the dia of external thread

14 Which term describes the axial movement of screw in one complete turn?

A Lead

B Flank

C Pitch

D Depth

15 How the size of drill bit is measured?

A Between flutes

B Between the lands

C Between web

D Neck diameter

16 What is the purpose of type ‘S’ twist drill?

A Used for hard material

B Used for high carbon steel

C Used for soft and tough material

D Used for normal low carbon steel

17 Determine the drill size for finishing ø19 mm reaming hole (as per table under size 0.2 & over size 0.05 mm)?

A 18.75 mm

B 19.00 mm

C 19.25 mm

D 19.05 mm

18 What is the drill size for ø15 mm reaming hole?

A 14.75 mm

B 14.50 mm

C 15.25 mm

D 14.65 mm

19 What is the name of the operation producing flat seat on drilled hole?

A Drilling

B Spot facing

C Counter sinking

D Counter boring

20 What is the purpose of flute in drill?

A To drive out the chips

B To reduce the weight

C To reduce the cost

D To increase the speed

21 What is the formula to calculate the blank size of external thread (where p=pitch and d=depth)?

A D = d – p/10

B D = d + p/10

C D = d x p/10

D D = d ÷ p/10

22 What is the size of drilled hole for reaming ø 10 mm?

A 8.5 mm

B 9.75 mm

C 10.00 mm

D 10.25 mm

23 Calculate the reading of vernier micrometer?

A 9.923 mm

B 9.963 mm

C 9.563 mm

D 9.763 mm

24 Which cast iron has the ability to minimize tool chatter in machine tools?

A Grey cast iron

B White cast iron

C Nodular cast iron

D Malleable cast iron

25 Why lime stone serves as flux in the blast furnace?

A To form molten slag

B To supply the oxygen

C To burn the carbon in coke

D To increase the melting point of ore

26 Which micrometer having provision of interchangeable anvils?

A Depth micrometer

B Inside micrometer

C Outside micrometer

D Screw thread micrometer

27 Which factor determine the selection of wire in screw thread micrometer?

A Thread angle

B Type of thread and pitch

C Root and crest

D Major diameter

28 What is measured with telescopic gauge?

A Depth

B External dimension

C Angular dimension

D Size of holes, slots and recesses

Level 3

1 Why hand reamers have uneven spacing of teeth?

A Reduce chattering

B Remove more metals

C Increase the efficiency

D Increase the life of the tool

2 What is the reason for over heated drill while drilling?

A Drill held not correctly

B Work is not rigidly held

C Clearance angle is incorrect

D Flutes are clogged with chips

3 What will happen if the clearance angle of drill is more?

A Cutting edge will be blunt

B Cutting edge will not be sharp

C Cutting edge will become weak

D Cutting edge will not cut material

4 What will happen if the spindle running out of the centre while drilling?

A Drill will break

B Drills are over heated

C Drill make rough hole

D Over sized holes are made

5 What is to be done after dressing the grinding wheel to run concentric?

A Truing

B Glazing

C Loading

D Dressing

6 What is the name of the defect, if the surface of the grinding wheel develops

smooth and shining appearance?

A Glazing

B Truing

C Loading

D Dressing

7 Why agricultural equipment is made up of wrought iron?

A Low cost

B Heavy weight

C Wear resistant

D Corrosion resistant

8 What is the effect if clearance angle is incorrect?

A Over sized holes

B Over heated drills

C Rough holes

D Broken drill

9 What is the type of defect on drilled hole?

A Rough holes

B Over heated drill

C Oversized holes

D Unequal flow of chips

10 What is the defect if pores of the grinding wheel get clogged?

A Drilling

B Glazing

C Loading

D Dressing

11 What is the reason for rough holes in drilling?

A Unequal point thinning

B Drill point not in centre

C Clearance angle is incorrect

D Drill cutting edges are not sharp

12 What is the reason if the drilled hole is larger than the drill size?

A Drill is not sharp

B Feed rate is too high

C Cutting speed is too high

D Unequal angle of cutting edge

13 Why drilled holes are over sized in drilling operation?

A Drill is not sharp

B Unequal lip length

C Feed rate is too high

D Cooling is insufficient

14 Why grey cast iron is widely used for machine tools?

A Rapid cooling

B Reduce vibration

C High tensile strength

D Very difficult to machining

15 What is the tap drill size for M20 x 1.5?

A 18.5

B 20

C 19

D 17

16 What is the drill hole size for dia 16 mm reamer?

A 15.75 mm

B 15.50 mm

C 14.65 mm

D 16 mm

17 Why drilled holes are over size than drill dia?

A Feed ratio is more

B Cooling is in effective

C Insufficient clearance angle

D Unequal length of cutting edge

18 What is the advantage of centre screw in die stock?

A To tighten the die

B To adjust the depth of cut

C To adjust the dia of internal thread

D To adjust the dia of external thread

19 Why precision instruments are made of invar steel?

A Durability

B Cheaper in cost

C Surface finishing is fine

D Least coefficient of expansion

20 Why lime stone is added to the ore in the blast furnace?

A To form molten slag

B To supply the oxygen

C To burnt the carbon in coke

D To increase the melting point of ore

Fitter Semester – 2

Module – 2 : Fitting Assembly

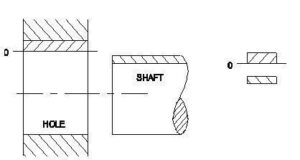

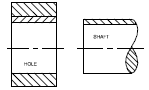

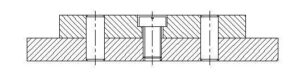

1 What is the name of the fit?

A Transition fit

B Clearance fit

C Shrinkage fit

D Interference fit

2 What is the term of the algebraic difference between a size, to its corresponding basic size?

A Deviation

B Upper deviation

C Lower deviation

D Actual deviation

3 What is the least count of vernier micrometer?

A 0.01 mm

B 0.02 mm

C 0.001 mm

D 0.002 mm

4 What is name of the tool?

A Flat scraper

B Hook scraper

C Half round scraper

D Three square scraper

5 Which instrument is used to measure the effective diameter of screw threads?

A Screw pitch gauge

B Outside micrometer

C Screw thread micrometer

D Screw thread caliper gauge

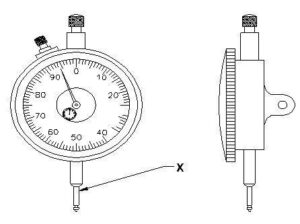

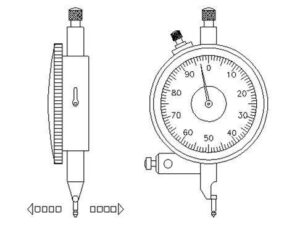

6 What is the name of part marked ‘x’ in dial gauge?

A Anvil

B Stem

C Pointer

D Plunger

7 What is the name of system if the size of the hole is kept constant, shaft is varied?

A Bilateral system

B Unilateral system

C Hole basis system

D Shaft basis system

8 Which device is used in conjunction with dial test indicator?

A Chuck

B Stand

C Tool rest

D Bench vice

9 What is the difference between maximum limit of size and the minimum limit of size?

A Tolerance

B Basic size

C Limits of size

D Upper deviation

10 Which is grade of tolerance?

A Bilateral tolerance

B Unilateral tolerance

C Fundamental tolerance

D Fundamental deviation

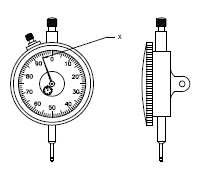

11 What is the name of part marked ‘X’?

A Anvil

B Steam

C Pointer

D Plunger

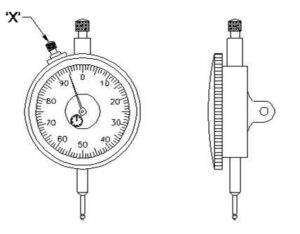

12 What is the name of the instrument?

A Dial vernier caliper

B Vernier micrometer

C Dial test indicator lever type

D Dial test indicator plunger type

13 What is the name of fit?

A Transition fit

B Shrinkage fit

C Clearance fit

D Interference fit

14 What is the name of the tool?

A Flat scraper

B Hook scraper

C Half round scraper

D Triangular scraper

15 What is the name of the part marked ‘X’ of lever type dial test indicator?

A Pivot

B Lever

C Stylus

D Scroll

16 What is the expression of 30H7/g6?

A Fit

B Limits

C Deviation

D Tolerance

17 What is the type of fit if the maximum size hole is larger than minimum size of shaft?

A Shrinkage fit

B Transition fit

C Clearance fit

D Interference fit

18 What is the name of the part marked ‘X’ in dial test indicator?

A Stem

B Pointer

C Back plug

D Bezel clamp

19 What is the angle of holding the scrapers for soft metal?

A 30°

B 60°

C 40°

D 20°

20 What is marked as ‘X’?

A Minimum limit

B Maximum limit

C Lower deviation

D Upper deviation

21 What is the upper deviation of the component size 0.0080.005 20

A 0.005

B 0.008

C 19.995

D 20.008

22 What is marked as ‘X’?

A Limit

B Tolerance zone

C Lower deviation

D Upper deviation

23 Which part indicates the reading of dial test indicator?

A Stem

B Anvil

C Pointer

D Plunger

24 What is the name of operation?

A Filing

B Drilling

C Scraping

D Chiseling

25 Which scraper is used to scrape the centre portion of large flat surface?

A Flat scraper

B Hook scraper

C Triangle scraper

D Bull-nose scraper

26 What is the name of the instrument?

A Screw pitch gauge

B Outside micrometer

C Screw thread micrometer

D Screw thread caliper gauge

27 Which instrument is used to magnify small variation in sizes by means of

pointer on a graduated dial?

A Dial test indicator

B Inside micrometer

C Dial vernier caliper

D Vernier micrometer

28 What is the smaller of the two limits of size?

A Actual size

B Maximum limit of size

C Minimum limit of size

D Limit of size

29 What is the number of fundamental deviation in the BIS system?

A 25

B 20

C 15

D 26

30 How many fundamental tolerance grades are available?

A 18 grade

B 25 grade

C 15 grade

D 12 grade

31 Which precision instrument is used for comparing and determining the

variation in the sizes of the component?

A Micrometer

B Comparators

C Dial test indicator

D Vernier bevel protector

32 What mechanism is used in the lever type dial test indicator?

A Screw and nut

B Rack and pinion

C Lever and scroll

D Worm and worm wheel

33 Which comparator is used in mass production?

A Optical

B Pneumatic

C Electronics

D Mechanical

34 Which gauge used to check internal thread of components?

A Thread ring gauge

B Taper ring gauge

C Thread plug gauge

D Caliper gauge

Level 2

1 What is the upper limit of the component size 0.008

0.005 20

A 0.005 mm

B 0.008 mm

C 19.995 mm

D 20.008 mm

2 What is the term used for the relationship exists between two mating parts?

A Fit

B Limit

C Tolerance

D Allowance

3 Which part of vernier micrometer is marked with vernier scale graduation?

A Anvil

B Frame

C Thimble

D Barrel

4 What is the lower limit of size, if dimension is stated as ø 0.021

0.000 25

A 24.85 mm

B 24.75 mm

C 25.00 mm

D 25.021 mm

5 What is the algebraic difference between the actual size and its corresponding basic size?

A Deviation

B Tolerance

C Actual deviation

D Upper deviation

6 Which scraper is used to scrape small diameter holes and deburing edges of holes?

A Flat scraper

B Hook scraper

C Triangular scraper

D Bull-nose scraper

7 Which scraper is used for scraping large bearing surface?

A Flat scraper

B Hook scraper

C Triangular scraper

D Bull-nose scraper

8 What is the maximum limit of size if the basic size of the hole is 25 mm and

the deviation is ±0.2mm?

A 25.2 mm

B 24.8 mm

C 25.02 mm

D 24.08 mm

9 What is the maximum limit of size if size on drawing is 0.12

0.21 20

A 19.988 mm

B 19.979 mm

C 20.012 mm

D 20.021 mm

10 Which term indicates the difference between the maximum limit of size and minimum limit of size?

A Deviation

B Tolerance

C Actual size

D Upper deviation

11 Which type of fit, the tolerance zone of hole is below the tolerance zone of shaft?

A Transition fit

B Clearance fit

C Shrinkage fit

D Interference fit

12 Which term indicates the algebraic difference between the actual size and its corresponding basic size?

A Deviation

B Actual deviation

C Upper deviation

D Lower deviation

13 What is marked as ‘X’ in hole basic system?

A Tolerance

B Maximum dia

C Lower deviation

D Upper deviation

14 What is the lower limit of size in dimension of 0.028

0.007 20

A 19.988 mm

B 20.028 mm

C 20.007 mm

D 19.979 mm

15 What is the lower limit of size, if dimension is stated as ø 0.021

0.000 24

?

A 24.85 mm

B 24.75 mm

C 24.000 mm

D 25.021 mm

16 What is the extreme permissible sizes within which the operator is expected to make the component?

A Basic size

B Actual size

C Nominal size

D Limits of size

17 What is the size of the component by actual measurement after it is manufactured?

A Limit size

B Actual size

C Maximum size

D Minimum size

18 A dimension is stated as 25 ± 0.02 mm in a drawing. What is the tolerance?

A +0.02 mm

B -0.02 mm

C 0.04 mm

D 25.00 mm

19 How to identify high spots while scraping?

A Prussian blue

B White chalk

C Copper sulphate

D Cellulose lacquer

Level 3

1 How chipped out scraper can be repaired?

A Filing

B Lapping

C Chiselling

D Grinding and honing

Fitter Semester – 2

Module – 3 : Turning

Level 1

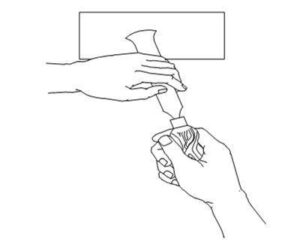

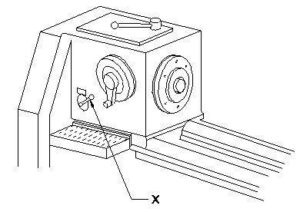

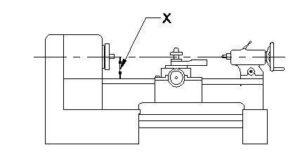

1 What is the name of the lathe specification marked ‘X’?

A Length of the bed

B Centre height of lathe

C Length between centre

D Diameter of work (Swing)

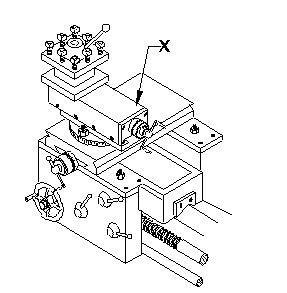

2 What is the name of the part marked ‘X’ in the lathe carriage?

A Tool post

B Top slide

C Cross slide

D Saddle lock

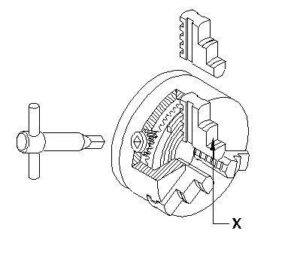

3 What is the name of the part marked ‘x’?

A Body

B Back plate

C External jaw

D Crown wheel

4 What is the name of operation?

A Square shoulder

B Filleted shoulder

C Bevelled shoulder

D Undercut shoulder

5 What type of cutting tool used in mass production?

A Solid tools

B Brazed tools

C Throw away type tools

D Inserted bits with holders

6 Which gauge is used to compare the profile of thread?

A Plug gauge

B Feeler gauge

C Radius gauge

D Screw pitch gauge

7 Which type of thread is used in screw jack?

A Vee thread

B Acme thread

C Knuckle thread

D Square thread

8 What is the name of the part marked ‘X’?

A Bed

B Tail stock

C Feed shaft

D Lead screw

Fitter (NSQF Level – 5) QB : Sem-2 – Mod-3 : Turning

9 What is the maximum swiveling angle of the compound rest in the lathe machine?

A 90°

B 180°

C 220°

D 360°

10 Which part is mainly supporting the lengthy job in lathe machine?

A Face plate

B Steady rest

C Dog carrier

D Dead centre

11 What is the name of part marked as ‘x’ of three jaw chuck?

A Body

B Back plate

C Internal jaw

D External jaw

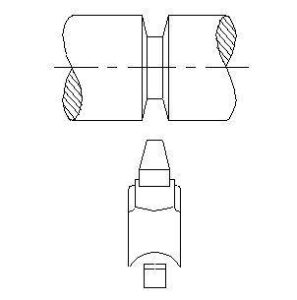

12 Which tool materials are manufactured by powder metallurgy technique?

A Carbides

B High speed steel

C High carbon steel

D Medium carbon steel

13 Which angle of the tool prevents from getting jamed in the groove and causes breakage?

A Side rake angle

B Side relief angle

C Side clearance angle

D Front clearance angle

14 What is the unit of cutting speed in turning?

A mm/sec

B m/sec

C m/min

D mm/min

Mod-3 : Turning

15 What is the type of operation is carried out?

A Straight groove

B Vee groove

C Round groove

D Square groove

17 What is the name of porition between root and crest of the thread?

A Root

B Flank

C Depth

D Thread angle

18 What is the principle of dial test indicator?

A Sliding

B Screw and nut

C Rack and pinion

D Worm and worm wheel

19 Which dimension is measured by using screw thread micrometer?

A Pitch of screw thread

B Minor dia of screw thread

C Major dia of screw thread

D Effective dia of screw thread

20 What type of power transmission is transmitted by spur gear?

A Parallel transmission

B Angular transmission

C Intersecting transmission

D Perpendicular transmission

21 How many types of bed ways are in centre lathe machine?

A 2

B 3

C 5

D 4

22 What is the name of instrument?

A Vernier micrometer

B Outside micrometer

C Three wire micrometer

D Screw thread micrometer

23 What is the name of part marked as ‘X’ in centre lathe?

A Apron

B Saddle

C Gross slide

D Compound rest

24 What is the name of part marked as ‘X’?

A Clutch

B Feed selector

C Lathe spindle

D Feed direction lever

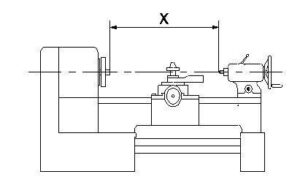

25 What is the name the specification of lathe marked as ‘X’?

A Bed length

B Centre height

C Swing diameter

D Between the center of lathe

26 What is the name of gauge?

A Ring gauge

B Screw pitch gauge

C Feeler gauge

D Radius gauge

27 Which is the range of metric screw thread dimension is measured by 8screw thread micrometer?

A M1 to M6

B M1 to M12

C M1 to M30

D M1 to M32

Level 2

1 What is the merit of three jaw chuck in lathe machine?

A Work can be set with ease

B Run out cannot be corrected

C Only round and hexagonal components can be held

D Accuracy decreases as chuck gets worn out

2 What is the de-merit of the four jaw chuck?

A Jaws are reversible

B Irregular shape job can be held

C Heavy cuts can be given

D Small and finished work will be damaged

3 Which type of rake angle make slope from the front towards back of the tool?

A End rake angle

B Side rake angle

C Negative rake angle

D Positive top rake angle

4 What is the name of the operation carried out in turning to remove burr and sharpness from the edge of component?

A Grooving

B Chamfering

C Step turning

D Plain turning

5 Find out the spindle speed for turning dia 40mm cast iron rod, if the cutting speed is 15 m/min?

A 119.3 rpm

B 100.3 rpm

C 219.3 rpm

D 109.4 rpm

6 Which is the vertical distance from crest to the root?

A Lead

B Flank

C Pitch

D Depth

7 Calculate the blank size for external threading M16 x 2.0?

A 14.0 mm

B 15.8 mm

C 16.0 mm

D 18.0 mm

8 What is the de-merit of 3 jaw chuck??

A Work can be set with ease

B Internal and external jaws are available

C Accuracy decreases

D A wide range of cylindrical and hexagonal work can be held

9 What is the use of screw pitch gauge?

A Check lead of the thread

B Check the pitch of the thread

C Check the minor dia of thread

D Check the major dia of thread

10 What is the purpose of back gear unit in lathe machine?

A Reduce the spindle speed

B Increase the spindle speed

C Quick change spindle speed

D To avoid abnormal impact on spindle

11 What is the range of pitch that can be measured by screw thread micrometer?

A 0.01 to 0.5 mm

B 0.02 to 3.5 mm

C 0.25 to 3.5 mm

D 0.50 to 5.0 mm

Level 3

1 What will be the effect, if the carriage is not locked while facing?

A Correct face

B Convex face

C Concave face

D Pip left in the centre

2 What is the defect caused if the tool is not set to the correct centre height `while facing?

A Convex face

B Concave face

C Pip left in the centre

D Rough surface on the face

Module – 4 : Basic Maintenance

Level 1

1 Which chart is used to record the skill of the operator in practice?

A Testing chart

B Levelling chart

C Geometric chart

D Performance chart

2 Which bearing withstands load is parallel to its axis?

A Needle bearing

B Thrust bearing

C Plain bearing

D Split bearing

3 Which belongs to Total Productive Maintenance?

A Supply defective goods to the customers

B Unscheduled maintenance

C Produces goods without increasing product quality

D Reduces maintenance cost

4 What is the high level formula for the lean manufacturing OEE?

A Availability x Quantity x Quality

B Availability x Productivity x Quality

C Product output x Quality x Availability

D Product output x Quantity x Quality

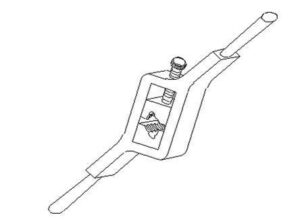

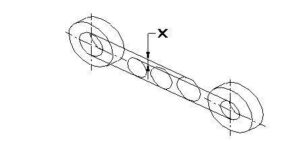

5 Identify the method of assembly technique?

A Dowelling

B Pinning

C Peening

D Staking

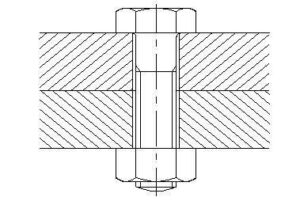

6 Identify the type of bolt?

A Bolt with clearance hole

B Body fit bolt

C Anti-fatigue bolt

D ‘T’ bolt

7 Name the type of part shown in assembly technique.

A Taper pin

B Split pin

C Cotter pin

D Spring pin

Level 2

1 What is the use of dowel in assembly technique?

A Accurate positioning of two or more parts

B Securing components together

C Eliminate the need for drilling

D Increase the efficiency of fit

2 Which maintenance record mention the date of commissioning of machine?

A Inspection check list

B Equipment record

C Product manual

D Servicing manual

3 What is the name of activity carried out to prevent break down of machinery in basic maintenance?

A Routine maintenance

B Preventive maintenance

C Repairing activity

D Inspection activity

4 What is the use of spring pins?

A Easy assembly and disassembly of parts

B Locate assemblies with wide tolerance in corresponding holes

C Retain the parts in assembly

D Accurate positioning of parts

5 Which bolt in the assembly prevent the relative movement between the workpieces?

A Anti-fatigue bolt

B ‘T’ bolt

C Body fit bolt

D Self locking bolt

6 Which assembly technique is similar to riveting method?

A Dowelling

B Pinning

C Peening

D Staking

Level 3

1 Why extra clearance given between bearing and journal in the aluminium alloy bearing?

A To overcome high thermal expansion

B To overcome linear expansion

C To overcome coefficient expansion

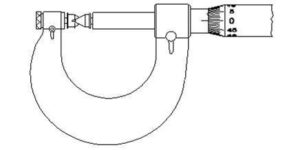

D To overcome lubricant to flow freely